Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

The growing demand for versatile and durable materials in both home and industrial applications has positioned Plastic Cladding Sheets at the forefront of construction and design solutions. According to a recent report by Market Research Future, the global plastic cladding market is projected to reach $8.5 billion by 2025, driven by the increasing preference for lightweight and weather-resistant materials that ensure longevity and reduced maintenance costs. As industries continue to embrace sustainability, the innovative uses of Plastic Cladding Sheets across various sectors—from residential facades to industrial enclosures—highlight their importance in modern building practices. Understanding the comparative advantages of different types of plastic cladding is crucial for both homeowners and industry professionals aiming to maximize aesthetic appeal and functionality. This blog will explore the intricacies of mastering Plastic Cladding Sheets, offering insights into their applications and performance across various environments.

Plastic cladding sheets have emerged as a versatile solution in both home and industrial applications due to their numerous advantages. In residential settings, these sheets are often utilized for exterior wall cladding, offering an attractive finish while providing durability and resistance to weather elements. Homeowners appreciate the aesthetic versatility as these sheets come in various colors and textures, allowing for creative customization. Additionally, their lightweight nature and easy installation make them a popular choice for renovations, giving homes an instant upgrade without extensive labor or costs.

In industrial environments, the functionality of plastic cladding sheets truly shines. These sheets are employed not only for wall protection but also in hygiene-sensitive areas such as food processing plants and hospitals. Their non-porous surface is easy to clean, helping maintain stringent health standards. Moreover, the chemical resistance of these materials makes them ideal for environments where exposure to corrosive substances is a concern. From manufacturing facilities to warehouses, plastic cladding sheets are proving to be an indispensable asset, capable of meeting the diverse demands of various industries while ensuring safety and longevity.

When selecting plastic cladding materials for both home and industry applications, several key factors must be taken into account to ensure optimal performance and durability. According to a report by Grand View Research, the global plastic cladding market is expected to reach USD 12 billion by 2025, indicating a significant demand for quality materials. One major consideration is the type of plastic—options such as PVC, polycarbonate, and acrylic each offer different advantages in terms of strength, UV resistance, and insulation properties. For instance, polycarbonate is renowned for its high impact resistance, making it ideal for industrial applications where durability is paramount.

Tips: Always check the weather resistance rating of the plastic cladding you are considering. A high rating will ensure longevity even in harsh environmental conditions. Furthermore, consider the aesthetic appeal of the material—different plastics can mimic the look of wood, metal, or stone, allowing for versatile design options.

Another important factor is the fire rating of the material. The International Code Council emphasizes that cladding systems must meet specific fire safety standards to protect buildings and occupants. For residential applications, lightweight materials with a Class A fire rating are recommended to enhance safety while providing architectural flexibility.

Tips: Consult with an expert or a supplier who can provide insights into the latest fire safety regulations related to plastic cladding, ensuring compliance and peace of mind.

When it comes to installing plastic cladding sheets, efficiency is key to achieving a durable and aesthetically pleasing finish. One innovative technique that has gained popularity is the use of pre-formed panels. These panels arrive at the site ready to install, significantly reducing the time and labor involved in the process. By minimizing cutting on-site, the risk of waste and errors decreases, which in turn contributes to a smoother installation experience.

Additionally, employing specialized adhesive systems instead of mechanical fasteners can streamline the attachment process. These adhesives provide a strong bond that allows for quick application, ensuring that the sheets adhere securely while also creating a seamless look. Furthermore, using a leveling system during installation can help ensure that the sheets are perfectly aligned, enhancing both function and appearance. With these innovative techniques, anyone can master the art of installing plastic cladding sheets, whether for residential renovations or industrial projects.

When it comes to maintaining plastic cladding sheets, a few essential tips can significantly enhance their longevity and performance in both home and industry applications. Regular cleaning is vital; using a mild detergent and soft cloth will help remove dirt and prevent buildup that could compromise the material. For more stubborn stains, consider using a specialized cleaner that is compatible with plastic surfaces.

Another crucial aspect is to inspect the cladding regularly for signs of wear or damage, especially after extreme weather events. Early detection of cracks or discoloration can prevent larger issues down the line. Additionally, consider applying a UV protectant to the surface to stave off fading and deterioration caused by sun exposure.

Lastly, ensuring proper installation is key. Utilizing high-quality fasteners and materials during installation will not only contribute to the aesthetic appeal but also enhance stability and reduce the chances of moisture intrusion, a common enemy of plastic cladding. By following these tips, you can effectively extend the life of your plastic cladding sheets while maintaining their functional and visual integrity.

| Application Area | Plastic Cladding Type | Maintenance Frequency | Recommended Cleaning Method | Expected Lifespan (Years) |

|---|---|---|---|---|

| Residential Interiors | PVC Cladding | Annually | Mild soap and warm water | 20 |

| Commercial Exteriors | Polycarbonate Cladding | Biannually | Window cleaner and soft cloth | 25 |

| Industrial Applications | FRP Cladding | Quarterly | Pressure washing | 30 |

| Agricultural Buildings | HDPE Cladding | Every 6 months | Diluted vinegar solution | 15 |

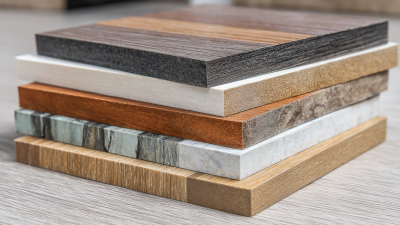

When choosing cladding materials for your home or industry, the debate often centers around

plastic cladding versus traditional cladding

solutions like wood, stone, or metal. One of the primary advantages of plastic cladding is its

resistance to moisture and rot, making it an ideal choice for environments prone to dampness.

Additionally, plastic cladding comes in a variety of styles and colors, providing greater design

flexibility without compromising durability.

Tip: When considering plastic

cladding, ensure you select UV-resistant materials to prevent

discoloration and degradation over time. This will enhance the longevity of your investment, making

it a more sustainable choice for both residential and commercial applications.

On the other hand, traditional cladding solutions offer timeless aesthetics and can increase the

overall value of a property. However, they often require more maintenance, such as regular

painting or staining, which can add to long-term costs. The long-term performance of these materials

may vary significantly based on the local climate and overall building design.

Tip: If you prefer the look of

traditional materials but want to minimize maintenance, consider composite options

that combine the best of both worlds, offering the warmth of natural aesthetics with the durability

of synthetic materials.