Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

Choosing the right Plastic Cladding Sheets for your construction projects is crucial. Industry reports indicate that plastic cladding materials have become popular due to their durability and versatility. According to David Roberts, a leading expert in the field, “Selecting the proper cladding can define the project’s success.”

Designers and builders need to consider several factors when choosing these materials. The aesthetic appeal is important; color and texture can enhance a space. Moreover, the environmental impact should not be overlooked. Reports show that nearly 40% of plastic materials are not recycled effectively. This raises questions about sustainability in the industry.

Understanding the qualities of Plastic Cladding Sheets can guide better decisions. While they offer great potential, choosing the wrong type can lead to future complications. There’s a growing need for education on this product to help avoid common pitfalls. As the industry evolves, so do the choices we face. It’s important to reflect on the implications and strive for smarter selections.

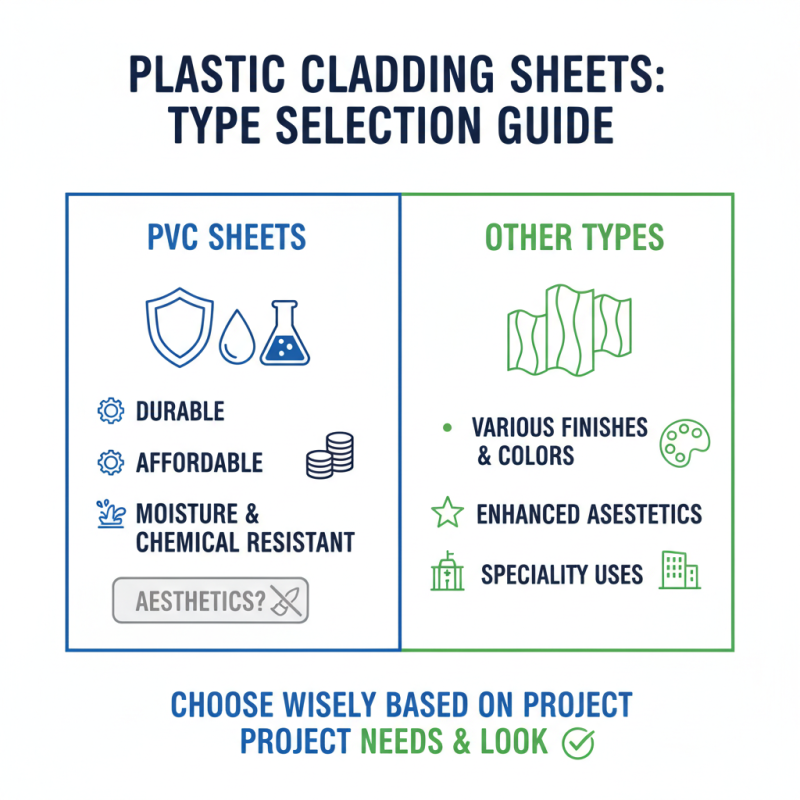

When selecting plastic cladding sheets, it's crucial to understand the various types available. Polyvinyl chloride (PVC) sheets are popular for their durability and affordability. They resist moisture and chemicals, making them suitable for many environments. However, their appearance may not appeal to everyone. Consider how aesthetics will play a role in your project.

Polycarbonate sheets offer excellent impact resistance and insulation properties. They can be transparent or opaque, fitting different architectural styles. Yet, they can be more expensive. Weighing cost against performance is essential. Acrylic sheets are another option. They are lighter and can provide a glossy finish. This material can scratch easily, which might lead to some regret later on.

It’s essential to reflect on the specific needs of your project. Each type of sheet has its pros and cons. The right choice often depends on your priorities: durability, cost, or visual appeal. Mistakes can be made if these factors aren't thoroughly considered. Take time to research and visualize how each option fits into your overall design.

When selecting plastic cladding sheets, durability and weather resistance are paramount factors. According to industry reports, high-quality plastic cladding can withstand extreme temperatures, ranging from -40°F to 140°F. This remarkable range ensures that the material won’t warp or crack under harsh conditions. Proper UV resistance is also crucial, protecting the cladding from sun damage and extending its lifespan. The right materials can last 20 years or more with minimal maintenance.

Tips: Look for cladding with a solid warranty. A long warranty often signals durability. Check for materials that have been tested against severe weather conditions.

Another point to consider involves installation. Even the best materials can fail if not installed correctly. Incorrect installation may lead to gaps, allowing moisture to penetrate. This issue can weaken the cladding, leading to costly repairs down the line. Research different installation techniques and choose trusted professionals.

Tips: Don’t rush the installation process. Take your time to plan carefully. Invest in quality tools, as they can make a significant difference.

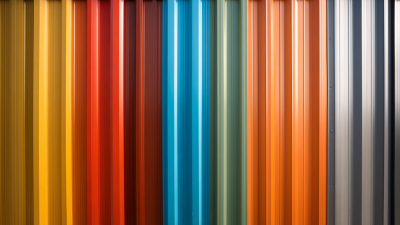

When choosing plastic cladding sheets, aesthetics play a crucial role. Colors and textures can significantly impact the overall design. Recent industry studies reveal that 73% of consumers prioritize visual appeal when selecting materials. Vibrant colors can enhance the ambiance of a space, while natural textures often mimic wood or stone. This allows for versatility in design.

Consider earthy tones or bold hues based on your project’s theme. For instance, light colors can make spaces feel larger, while dark tones add sophistication. The texture can also alter perceptions. Smooth surfaces tend to appear modern, whereas textured options provide warmth. Reports indicate that textured sheets are increasingly popular, with a 40% rise in preference over the last five years.

However, it’s essential to reflect on your choices. Not every color or texture may suit your environment. For instance, vibrant colors can overwhelm small spaces. Sometimes, a less exciting option might be more appropriate. Balancing aesthetics with functionality is key. Your final decision should consider both the visual impact and the practical use of the cladding sheets. This balance can be challenging, but it’s crucial for a successful project.

When considering plastic cladding sheets, cost-effectiveness is key. Budget constraints often dictate material choices. High-quality cladding can be more expensive upfront. However, it may offer savings in maintenance and durability over time. Cheaper options might seem appealing. Yet, they can lead to higher repair costs in the long run.

Evaluating the costs is crucial. Analyze your project budget thoroughly. Look for hidden expenses like installation and long-term upkeep. Choosing the right thickness and finish can impact the overall cost. Remember, not all cladding sheets are created equal. Take time to research material properties and warranties. Sometimes, cheaper sheets might not perform well in harsh weather conditions.

Reflecting on your needs can guide the decision. Think about how long you plan to use the cladding. Consider aesthetics versus functionality. Investing in durable materials can enhance the overall appeal of your project. Balancing cost and quality may feel challenging, but it is vital. This choice directly affects the longevity and appearance of your work.

When selecting plastic cladding sheets, understanding installation and maintenance requirements is crucial. Many projects underestimate the skills needed for proper installation. Industry data indicates that poorly installed cladding can reduce a building's energy efficiency by up to 40%. This is not just a number; it affects comfort and costs over time.

Tip: Always review the installation guidelines from the manufacturer. Proper adherence to these instructions can ensure optimal performance. Many experts recommend consulting with professionals, especially for large-scale projects. Remember, a small oversight can lead to bigger issues later.

Maintenance is another key factor to consider. Plastic cladding is generally low maintenance, but it still requires periodic cleaning and inspection. Neglecting maintenance can accelerate wear and tear. The materials chosen should withstand local weather conditions effectively. For example, UV resistance is vital in sunny climates, as UV damage might degrade the material faster than expected.

Tip: Schedule routine checks every six months. This simple step can help you catch problems early. Regular cleaning extends the life of your cladding sheets, maximizing your investment. Taking these factors into account is essential for a successful project.

| Dimension | Material Type | Weight (kg/m²) | Thickness (mm) | Installation Method | Maintenance Frequency |

|---|---|---|---|---|---|

| 1220 x 2440 | PVC | 4.5 | 6 | Screw down | Annual |

| 2000 x 1000 | Polycarbonate | 6.0 | 10 | Snap fit | Biannual |

| 3000 x 1250 | Acrylic | 7.5 | 8 | Adhesive | Quarterly |

| 1500 x 3000 | FRP | 5.0 | 5 | Bolted | Annual |