Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

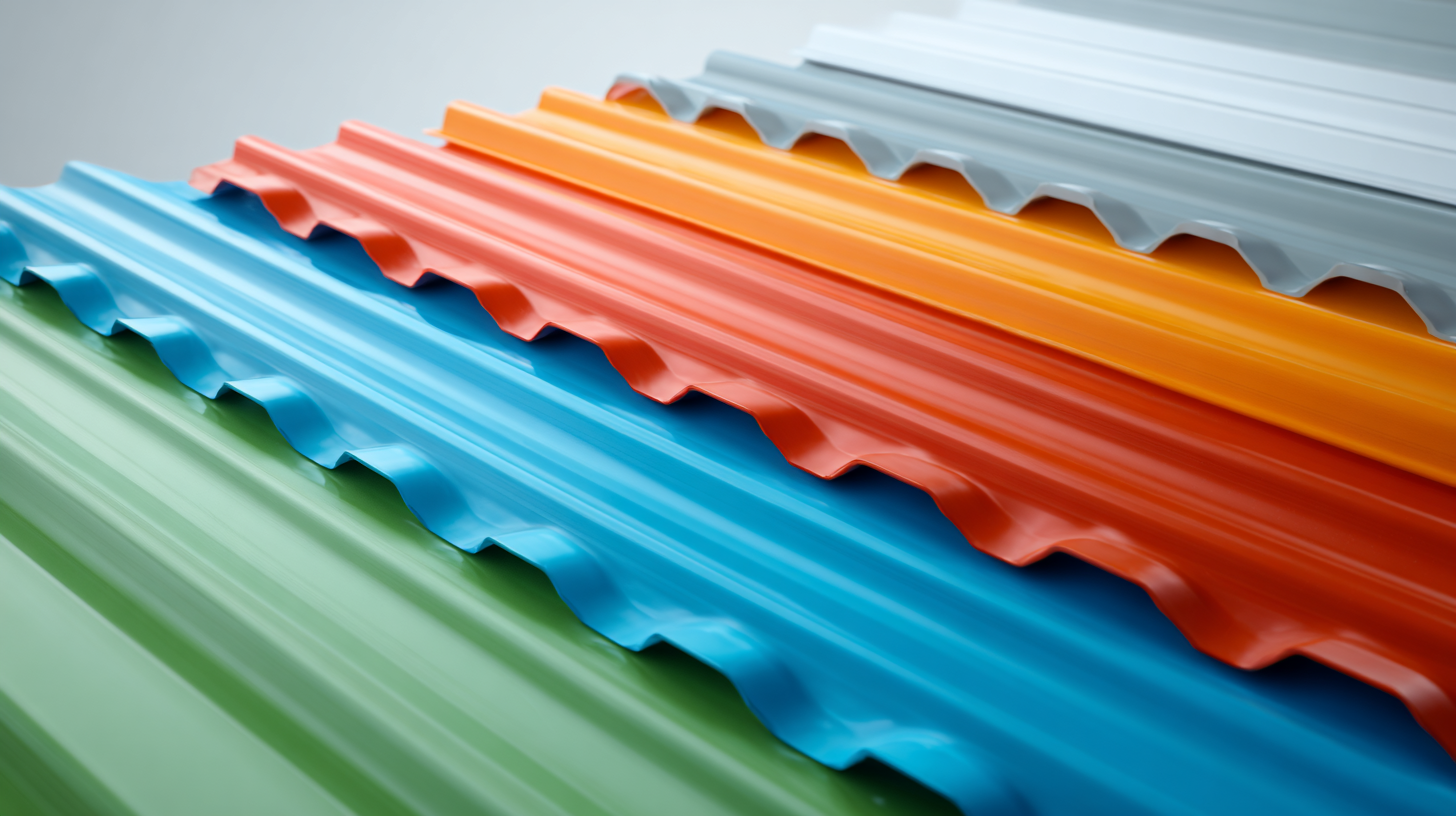

In recent years, the construction industry has seen a substantial shift towards sustainable materials, with plastic cladding sheets emerging as a popular choice among architects and builders. According to a comprehensive report by Smithers Pira, the global market for plastic cladding is projected to reach over $20 billion by 2025, driven by their durability, low maintenance, and resistance to weathering and pests. This growth reflects an increasing awareness of the benefits of using plastic in construction, where versatility and aesthetic appeal are paramount. Choosing the right plastic cladding sheets for your project not only enhances the visual aspect of a building but also contributes significantly to its longevity and environmental performance. As the options expand, understanding the various types and their specific advantages becomes essential for making informed decisions that align with both functional needs and design vision.

When it comes to selecting plastic cladding sheets for your project, understanding the different types available is crucial. Plastic cladding sheets are typically made from materials like PVC, acrylic, or polycarbonate, each serving distinct purposes. PVC sheets are known for their excellent durability and cost-effectiveness, making them ideal for applications in construction and industrial settings. Their ease of installation and maintenance also appeal to many homeowners looking for practical solutions.

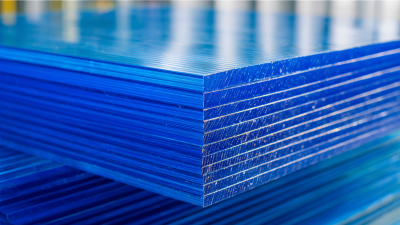

Acrylic sheets, on the other hand, are prized for their clarity and aesthetic appeal. They can mimic the appearance of glass while being lighter and more shatter-resistant. This makes them an excellent option for decorative applications or areas requiring natural light, such as skylights or greenhouse panels. Lastly, polycarbonate sheets offer superior impact resistance and thermal insulation, making them a popular choice for roofing or areas exposed to harsh weather. By recognizing the unique characteristics and advantages of each type, you can make an informed decision that aligns with your project needs.

When selecting plastic cladding sheets for your project, several key factors should be considered to ensure you make the best choice. First and foremost, think about the material's durability. Plastic cladding sheets vary in their resistance to weather elements, impacts, and UV rays. Options like polycarbonate and PVC are often favored for their robust nature and long lifespan, making them ideal for both aesthetic and protective purposes.

Additionally, consider the thickness and weight of the sheets. Thicker panels may offer better insulation and sturdiness, but they can also be more challenging to install. Weighing factors such as installation ease and structural requirements will help you determine the right balance for your project. Lastly, color and finish are crucial for visual appeal. Various textures and colors are available, allowing for customized looks that meet the design needs of your space. Remember, the right choice not only enhances the appearance but ensures functional longevity.

| Factor | Consideration | Importance | Example Materials |

|---|---|---|---|

| Durability | Resistance to Impact and Weather | High | Polycarbonate, PVC |

| Weight | Ease of Handling and Installation | Medium | Acrylic, HDPE |

| Aesthetic | Visual Appeal and Color Options | High | PVC, Composite |

| Cost | Budget Compatibility | Medium | Various Options |

| Maintenance | Ease of Cleaning and Upkeep | Medium | PVC, Polycarbonate |

When selecting plastic cladding sheets for your project, understanding the durability and lifespan of various options is crucial. Recent industry reports indicate that high-density polyethylene (HDPE) and polyvinyl chloride (PVC) are among the most durable choices available. According to a 2022 market analysis by Smithers Pira, HDPE sheets can have a lifespan of over 50 years when properly maintained, making them ideal for applications in both residential and commercial building exteriors. Their inherent resistance to moisture, chemicals, and UV radiation ensures they remain intact under various environmental conditions.

On the other hand, PVC cladding is also highly durable, with a lifespan that typically ranges between 20 to 30 years. A study conducted by the American Plastics Council highlighted that advancements in formulation have enhanced PVC’s weather resistance and its ability to withstand extreme temperatures. Moreover, both materials require minimal maintenance, reducing long-term costs for building owners. When choosing between these options, it's essential to consider the specific environmental factors your project will face, as well as the overall lifecycle costs, to make an informed decision that aligns with your durability requirements.

When embarking on a project that requires plastic cladding sheets, understanding the cost implications is essential for effective budgeting. According to a report by the Freedonia Group, the demand for plastic cladding is projected to grow by 4.5% annually, indicating an increasing preference for these materials in various applications, from residential to commercial. Prices can vary significantly based on the type of plastic used; for instance, polycarbonate sheets typically range from $3 to $5 per square foot, while PVC options can be found for as low as $1.50 per square foot. This variation is crucial for project managers to consider when estimating material costs.

Additionally, the lifecycle costs associated with plastic cladding sheets should not be overlooked. A study by Markets And Markets estimates that while the initial purchase price is important, factors such as maintenance, energy efficiency, and durability also contribute to the long-term expenses of the project. For example, polycarbonate sheets, despite their higher upfront cost, offer superior insulation properties that can lead to reduced energy bills over time. Thus, when budgeting for your project, it is vital to balance initial expenditures with potential savings, ensuring a comprehensive evaluation of your plastic cladding options.

When working with plastic cladding sheets, proper installation is essential to ensure durability and aesthetic appeal. One of the best practices to consider is preparing a clean and level surface. Before installation, make sure all debris, dust, and residues are removed. This not only enhances the adhesion of the panels but also provides a more professional finish to your project.

Another crucial tip is to use the correct tools and materials. Utilizing a fine-toothed saw for cutting plastic sheets helps to prevent chipping and ensures clean edges. Additionally, select screws or fasteners that are specifically designed for plastic to avoid issues like cracking. Remember to leave appropriate expansion gaps, as plastic can expand or contract with temperature changes, which is vital in preventing warping or buckling over time.

Lastly, consider using a sealant during the installation process. Applying a weather-resistant sealant around the edges and seams will protect against moisture infiltration and enhance the longevity of your cladding. Always follow the manufacturer's guidelines for any specific installation requirements, as this guarantees a successful and efficient application.