Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

In the realm of renovation projects, the choice of materials often dictates the success and longevity of the finished work. A noteworthy option for those seeking to enhance hygiene and aesthetics in their spaces is PVC hygienic wall cladding. As industry expert Dr. Emily Carter, a leading figure in interior design and building materials, emphasizes, "PVC hygienic wall cladding not only provides a sleek finish but also ensures an environment that is easy to clean and maintain.”

The versatility and durability of PVC hygienic wall cladding make it an ideal choice for a wide range of applications, from commercial kitchens to healthcare facilities. Its resistance to moisture, mold, and bacteria creates a safer environment, which is increasingly important in today's world. Moreover, the variety of colors and finishes available allows for customization that can suit any design preference while maintaining the necessary hygiene standards.

Incorporating PVC hygienic wall cladding into your next renovation project not only elevates the functionality of the space but also aligns with modern aesthetic trends. As we delve deeper into the benefits and applications of this innovative material, it becomes clear why it has become a preferred choice among architects and builders alike.

When considering materials for renovation projects, PVC hygienic wall cladding stands out for its impressive durability and low maintenance requirements. This type of cladding is specifically designed to resist moisture, making it an ideal choice for areas prone to humidity, such as kitchens, bathrooms, and laboratories. Unlike traditional materials like paint or wallpaper, PVC cladding does not peel or warp, ensuring that the walls remain intact and visually appealing over time. Its resistance to mold and bacteria contributes to a healthier environment, particularly in spaces where cleanliness is paramount.

In addition to its practical benefits, PVC hygienic wall cladding offers aesthetic flexibility. Available in a variety of colors and finishes, it can easily complement diverse design themes, allowing homeowners and designers to achieve a tailored look without sacrificing functionality. The installation process is straightforward, which can lead to reduced labor costs and time, further enhancing its appeal. Given its impressive lifespan and adaptability, PVC cladding emerges as a cost-effective investment for renovations, promising both aesthetic value and long-term performance.

When considering wall finishes for renovation projects, a comparison between PVC hygienic wall cladding and traditional options such as paint or wallpaper highlights significant advantages. PVC cladding is renowned for its durability and low maintenance requirements. According to a study by the European Plastics Industry, PVC wall cladding can last up to 25 years, far surpassing the lifespan of traditional paints, which typically require repainting every 5-7 years. This longevity not only reduces long-term costs but also minimizes renovation disruptions.

Another key benefit of PVC cladding is its superior hygiene and ease of cleaning. Traditional wall finishes may harbor bacteria and mold, prompting concerns in environments such as healthcare facilities and food processing areas. Research published in the Journal of Applied Microbiology indicated that PVC surfaces showed a 95% reduction in bacterial load compared to porous walls. This creates a safer environment, making PVC an ideal choice for commercial and institutional settings.

Tips: When choosing wall finishes, consider the specific needs of your space. For high-traffic areas, PVC cladding may provide a longer-lasting solution. Additionally, assess the cleaning requirements of any finish; opting for low-maintenance materials like PVC can save time and ensure better hygiene standards in the long run. Always ensure proper installation to maximize the benefits of the chosen material.

| Feature | PVC Hygienic Wall Cladding | Traditional Wall Finishes |

|---|---|---|

| Hygiene | Highly resistant to mold and bacteria | Susceptible to mold and bacteria growth |

| Maintenance | Easy to clean with antibacterial properties | Requires regular painting and sealing |

| Durability | Impact-resistant and long-lasting | Can chip and crack over time |

| Cost | Generally cost-effective for long-term use | Initial lower cost but higher long-term maintenance |

| Installation | Quick and easy installation process | Installation can be labor-intensive and time-consuming |

| Appearance | Modern and sleek finish | Traditional and varied but may look dated |

PVC hygienic wall cladding is increasingly recognized for its versatility and functionality across various industries. One of the most prominent applications is in the healthcare sector, where cleanliness and hygiene are of utmost importance. Hospitals, clinics, and laboratories benefit from PVC wall cladding's non-porous surface, which resists moisture and prevents the growth of bacteria and mold. This feature is crucial in maintaining sterile environments and ensuring patient safety. Ease of cleaning and maintenance makes PVC an attractive option for high-traffic areas that require frequent sanitation.

In addition to healthcare, PVC hygienic wall cladding is widely used in food processing and service environments. The food industry demands strict adherence to hygiene standards, and PVC cladding provides a seamless and durable barrier against contamination. Its resistance to chemicals and impact makes it ideal for kitchens, storage areas, and processing plants. With a variety of colors and finishes available, PVC cladding can effectively enhance the aesthetic appeal of a space without compromising its functionality. Furthermore, it is an excellent choice for commercial settings such as laboratories, schools, and veterinary practices, where hygiene and durability are paramount.

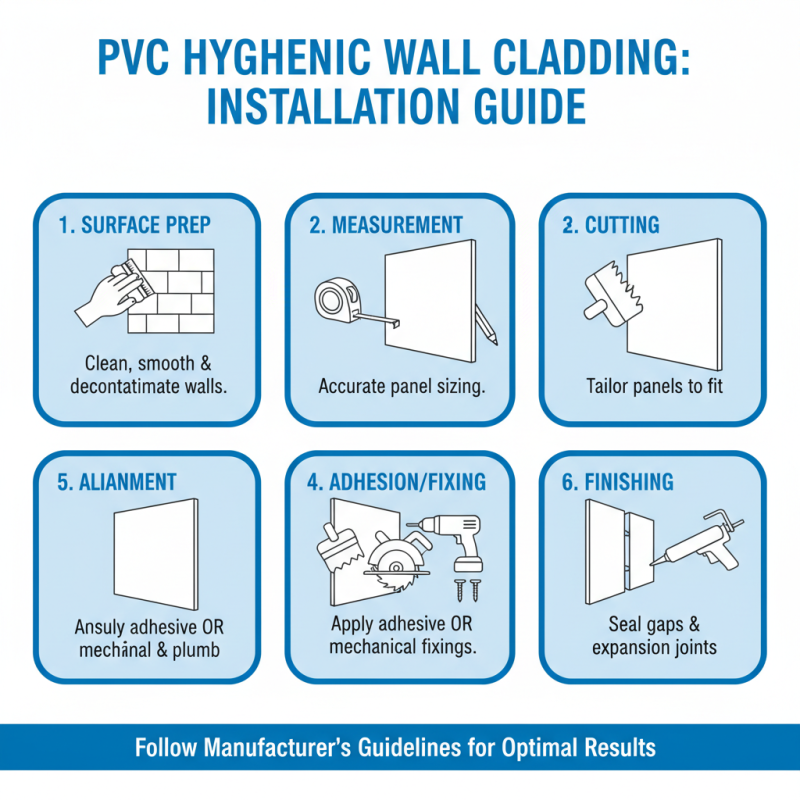

The installation process of PVC hygienic wall cladding is straightforward, making it an appealing choice for various renovation projects. Initially, proper surface preparation is essential. The walls should be cleaned, smoothed out, and free of any contaminants to ensure the cladding adheres effectively. Next, accurate measurements are taken to create panels that fit seamlessly. Depending on the area, either adhesive or a mechanical fixing system can be used to secure the panels in place. It's vital to follow the manufacturer's guidelines during this stage to guarantee optimal results, including considerations for gaps and expansion joints.

Once the installation is complete, maintenance of PVC wall cladding is relatively simple. Regular cleaning with mild detergents is recommended to maintain its hygienic properties, and it’s crucial to avoid harsh chemicals that can damage the surface. Inspecting the cladding periodically for any signs of wear or damage is also advisable; minor issues can often be rectified without replacing the entire panel. Overall, the combination of an easy installation process and low maintenance makes PVC hygienic wall cladding an ideal choice for both commercial and residential renovations.

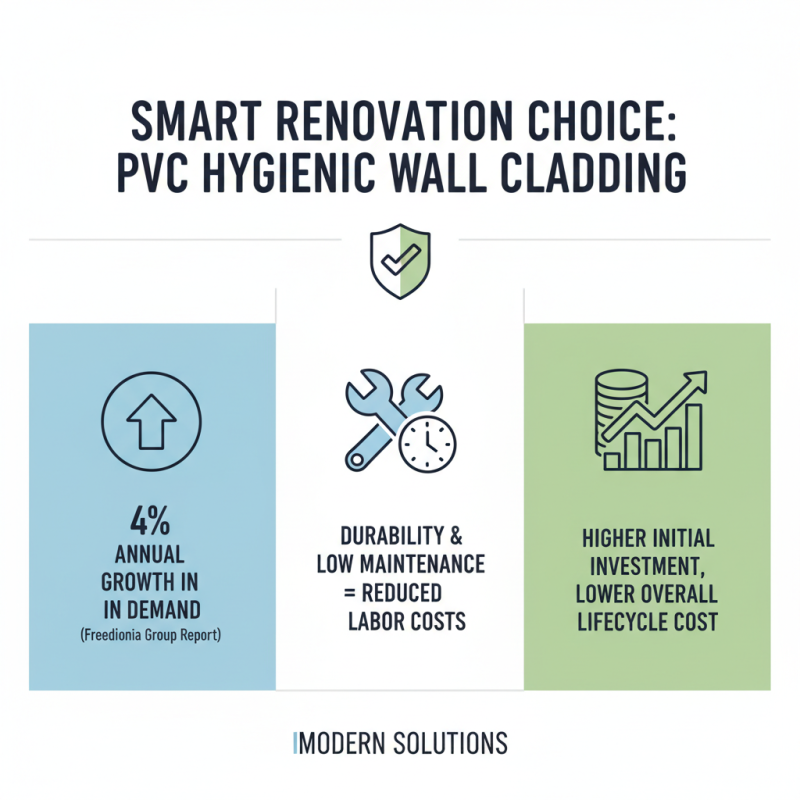

When considering materials for your next renovation, PVC hygienic wall cladding stands out as a cost-effective option. According to a report by the Freedonia Group, the demand for plastic wall coverings is projected to grow by 4% annually, driven by their durability and ease of maintenance. PVC cladding not only minimizes the need for frequent repairs but also provides a seamless surface that reduces cleaning time, which can significantly lower labor costs over the long term. The initial investment in PVC cladding may be higher than other materials, but the overall lifecycle cost tends to favor those who choose this modern solution.

Tips for maximizing the cost-effectiveness of PVC hygienic cladding include ensuring proper installation to avoid future repair expenses. Hiring trained professionals can ensure that your cladding will last, as improper installation can lead to costly damage over time. Additionally, when selecting colors or finishes, consider lighter shades that can reflect light and reduce energy costs by minimizing the need for artificial lighting.

Furthermore, it’s essential to anticipate future needs when renovating. The versatility of PVC cladding allows for easy modifications, making it a smart choice for spaces that may undergo changing functions over time. According to a study by Allied Market Research, the ability to quickly adapt your space not only adds value to your renovation but also contributes to a more sustainable building practice. This adaptability ensures that your investment remains relevant and economically viable well into the future.