Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

When embarking on a renovation or construction project, the selection of materials plays a pivotal role in achieving both aesthetic and functional goals. Among the myriad options available, Plastic Wall Panels have emerged as a popular choice due to their durability, ease of maintenance, and versatility. However, as appealing as they may seem, choosing the right Plastic Wall Panels for your project comes with its own set of challenges. From navigating the vast array of designs and colors to understanding the specific requirements for installation and maintenance, making an informed decision is crucial. This blog will delve into the common hurdles faced when selecting Plastic Wall Panels and present effective solutions that can guide you towards the best choices for your space. Discover how to overcome these challenges to enhance the overall success of your project.

When selecting plastic wall panels for your project, it is crucial to understand their key characteristics to ensure suitability. Plastic wall panels are known for their durability, moisture resistance, and ease of maintenance. However, the varying quality and specifications can lead to challenges in selection. For example, panels made of high-density polyethylene (HDPE) offer superior durability and resistance to impacts, making them ideal for high-traffic areas. Additionally, the panel thickness and design should be considered to match the project's requirements.

Tip: Always check the manufacturer's specifications for fire ratings, as not all plastic panels have the same level of fire resistance. This can drastically affect safety in certain applications.

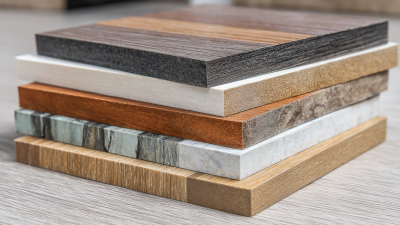

Another characteristic to watch for is the aesthetic versatility of plastic wall panels. They come in various colors and textures that can mimic other materials such as wood or stone, allowing for creative design opportunities. However, the finish can impact cleaning methods and longevity. Therefore, select a finish that’s appropriate for the environment it will be exposed to.

Tip: When in doubt, request samples to see how the panels look in your project space. This helps ensure that your choice complements the overall design and functionality needs.

When considering the integration of plastic wall panels into your design, assessing their cost-effectiveness is crucial, especially for budget-sensitive projects. According to a report by Grand View Research, the global market for plastic wall paneling is expected to reach $5.45 billion by 2027, reflecting a growing trend towards plastic materials in construction. This is largely due to their lightweight nature and lower installation costs, which can significantly reduce labor expenses. For instance, contractors have noted that installing plastic panels is approximately 30% quicker than traditional materials, allowing for faster project completion and potential savings.

However, it’s essential to evaluate the long-term durability and maintenance costs associated with plastic wall panels. While initial investment may be lower, the longevity and performance across various environments can impact overall cost-effectiveness. Research by IBISWorld indicates that while plastic panels can offer up to a 20% reduction in initial costs compared to wood or metal alternatives, they may require additional investment for UV protection and replacement every 10 to 15 years in harsher climates. Therefore, analyzing both upfront and ongoing costs will provide a clearer picture of budget requirements, ensuring that the final decision aligns with the project's financial framework.

When selecting plastic wall panels for construction or renovation projects, understanding their longevity and durability is crucial. Plastic wall panels are known for their low maintenance requirements and resistance to moisture, making them suitable for a variety of environments, from kitchens to bathrooms. Industry insights indicate that high-quality plastic panels can last anywhere from 10 to 30 years, depending on factors such as installation methods, exposure to sunlight, and environmental conditions.

Moreover, advancements in manufacturing technologies have significantly enhanced the resilience of plastic wall panels. Many modern panels are designed to withstand impacts, scratches, and UV degradation, which contributes to their long-term performance. While cheaper options might seem appealing, investing in higher-quality products can lead to substantial savings over time, as they reduce the frequency of replacements and maintenance. Understanding these aspects can help homeowners and contractors make informed decisions, ensuring that the chosen panels will not only meet aesthetic requirements but will also provide excellent durability for the years to come.

| Factors | Impact on Longevity | Common Lifespan (Years) | Maintenance Requirements |

|---|---|---|---|

| Material Quality | Higher quality materials typically enhance durability and resistance to wear. | 10-15 | Minimal, occasional cleaning recommended. |

| Environmental Conditions | Extreme temperatures and humidity can shorten lifespan. | 5-10 | Regular inspections required. |

| Installation Quality | Improper installation can lead to damage and decreased lifespan. | 8-12 | Check joints and seams periodically. |

| Exposure to Chemicals | Certain chemicals can degrade the material over time. | 5-10 | Avoid direct contact with harmful substances. |

| UV Exposure | UV light can lead to fading and brittleness. | 7-12 | Use UV-resistant coatings as needed. |

When selecting plastic wall panels for construction projects, sustainability plays a crucial role in decision-making. While plastic panels offer durability and ease of installation, their environmental impact compared to alternatives, such as wood or metal, raises concerns. According to a recent study by the Environmental Protection Agency, the production of plastic contributes significantly to greenhouse gas emissions, with estimates suggesting that it accounts for about 8-10% of global emissions. This highlights the urgent need for careful evaluation of material choices in order to minimize ecological footprints.

Tip: When considering plastic wall panels, look for options that are made from recycled materials or those that can be recycled after their lifespan. This can help reduce the strain on landfill systems and lower the overall environmental impact.

Moreover, the life-cycle analysis of plastic materials indicates that while they may have a lower upfront cost, their long-term effects can be detrimental. For instance, the energy required to manufacture and transport plastic far exceeds that of sustainably sourced wood. A report from the World Wildlife Fund indicates that sustainably harvested wood products have a significantly lower environmental impact, which makes them a worthy alternative when assessing overall sustainability.

Tip: Always research manufacturers for their sustainability standards, such as certifications and commitments to reducing environmental impact, to ensure that your project aligns with eco-friendly practices.

Installation of plastic wall panels can pose a unique set of challenges that, if not addressed, can lead to a less-than-ideal finish. According to a report by the Plastic Construction Association, improper installation is one of the leading causes of dissatisfaction in projects that utilize plastic cladding systems, affecting nearly 30% of installations. To achieve a seamless fit, it's crucial to familiarize yourself with the correct measurements and ensure all panels are cut with precision, adhering to manufacturer specifications.

Expert tips suggest that proper surface preparation is key to a successful installation. A clean, even surface contributes significantly to the adhesion and overall appearance of the panels. Furthermore, ensuring that proper expansion gaps are maintained can alleviate issues related to temperature fluctuations that may cause warping or buckling. Data from the Building and Construction Research Institute indicates that nearly 25% of installation failures are linked to inadequate attention to expansion and contraction needs. Utilizing quality adhesives and fasteners specific to plastic applications can also enhance durability and aesthetic appeal, leading to a project that not only looks great but stands the test of time.